ETAMASTER EC • Circular duct fans with EC motor

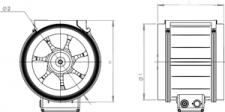

- Very compact helico-centifugal duct fan with energy-efficient EC motor and corrosion-resistant housing

Application

-

ETAMASTER EC fans are designed for use with round channels. Since the diameter of the channel is hardly exceeded by the fan housing, the ETAMASTER EC fan can be used in confined spaces.

The specially designed 3-dimensionally shaped rotor and stator blades ensure that they are correctly inflowed, so that the pressure profile on the surface of the blade is achieved much more effectively and with fewer losses. The highly efficient stator will also ensure that lost energy due to rotation-loaded flow at the rotor output (dynamic pressure) is converted into usable energy (static pressure). This combination results in a duct fan with the highest efficiency of its kind, as a result of which the ETAMASTER EC fans will reduce the operational costs enormously.

Because the motor is built into the stator hub, outside the air flow, the ETAMASTER EC fans can be used for slightly polluted air.

The EC technology (Electronic Commutation) is an intelligent technology that, by using the internal electronic control, eliminates slip losses in the motor and ensures that the motor always runs at the optimum voltage. This EC technology also guarantees that the efficiency of the energy used is many times higher, so that energy consumption is also much lower compared to AC motors.

The ETAMASTER EC fan is equipped with an energy-efficient EC motor, saving up to 35% compared to an ETAMASTER with a normal AC motor.

The EC technology makes easy speed control possible, without loss of efficiency. This means that the energy consumption of the ETAMASTER EC will also be many times lower at partial load compared to the AC motor.

They are used for ventilation in offices, schools, parking garages, industrial applications.

Composition

The compact housing has a mounting base and integrated connection box

- The housing is made of plastic (PPFG30) RAL 7012

- Helico centrifugal turbine with guide vanes for high efficiency

- EC motor with life-lubricated ball bearings

- Motor insulation class:

- ETAMASTER 150L EC 01 to ETAMASTER 355 EC 01: F

- ETAMASTER 355 EC 02 to.m. ETAMASTER 400 EC 01: B

- Motor protection class:

- ETAMASTER 150L EC 01 to ETAMASTER 200 EC 01: IP54

- ETAMASTER 250 EC 01 to ETAMASTER 355 EC 01: IP33

- ETAMASTER 355 EC 02 to.m. ETAMASTER 400 EC 01: IP20

- IP protection class of entire fan: IPX4

- Connection box IP44 with cable gland

- Internal electronic temperature monitoring

Accessories

- Mounting clamp, type BMK

- Protective grille, type BSV

- Potentiometer, type MTP010

- 3-position switches 0-10V, type MSS-D

Requesting information. Please wait a moment...